Digital twins have emerged as a transformative technology, revolutionizing various industries by enhancing efficiency, innovation, and decision-making processes. These virtual replicas of physical assets or systems offer a wide range of benefits, from predictive maintenance to optimized performance. This article delves into the myriad advantages of digital twins, their applications across different sectors, and the future potential they hold for modern industry.

What is a Digital Twin?

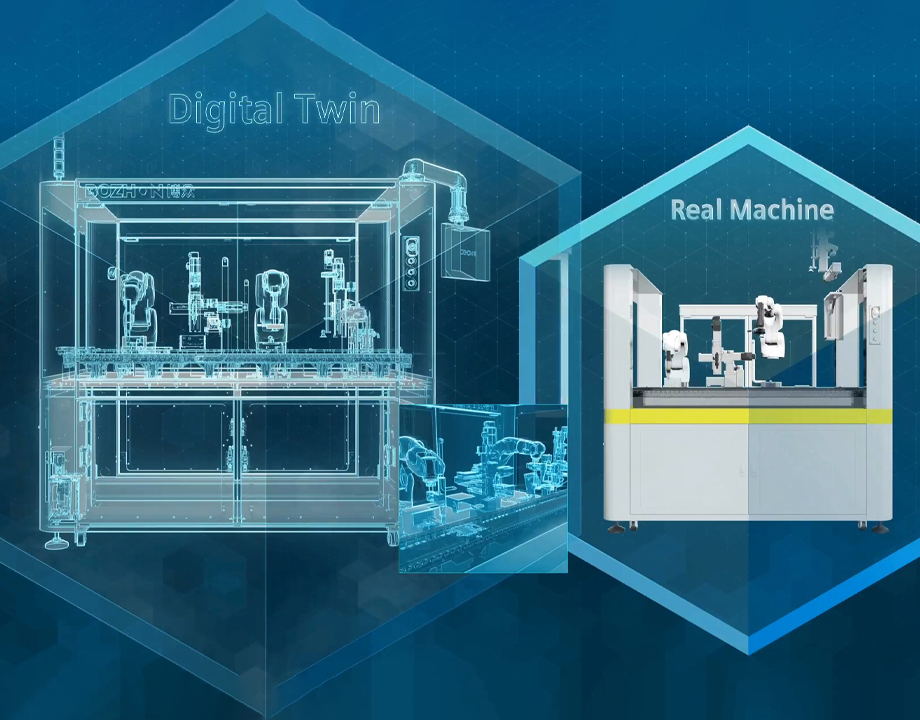

A digital twin is a virtual representation of a physical object, system, or process. This model is continuously updated with real-time data from its physical counterpart through sensors and other data sources. The digital twin mirrors the state and behaviour of the physical entity, allowing for simulations, analysis, and optimization.

Core Components of a Digital Twin

- Physical Asset: The real-world object or system being replicated.

- Digital Replica: The virtual model that mirrors the physical asset’s characteristics and behaviour.

- Data Connectivity: Sensors and IoT devices that provide real-time data to update the digital twin.

- Analytics Engine: Software that processes and analyzes the data to provide insights and predictions.

Benefits of Digital Twins in Modern Industry

1. Enhanced Predictive Maintenance

Predictive maintenance is one of the most significant advantages of digital twins. By continuously monitoring the physical asset and analyzing its performance data, digital twins can predict when a component is likely to fail or require maintenance. This approach allows for timely interventions, reducing unexpected downtime and extending the asset’s lifespan.

Example: In the aerospace industry, digital twins of aircraft engines can predict when parts might need maintenance or replacement, thereby preventing in-flight failures and improving safety.

2. Improved Operational Efficiency

Digital twins enable companies to simulate different scenarios and optimize processes before implementing changes in the real world. This simulation capability allows businesses to identify inefficiencies, test solutions, and make data-driven decisions to enhance overall operational efficiency.

Example: In manufacturing, digital twins can simulate production lines to identify bottlenecks and optimize workflows, leading to increased productivity and reduced costs.

3. Enhanced Product Design and Development

The iterative design process benefits greatly from digital twins. Engineers and designers can use digital twins to test and validate product designs under various conditions before physical prototypes are created. This approach accelerates the development cycle and reduces the costs associated with physical testing.

Example: Automotive manufacturers use digital twins to design and test new vehicle models virtually, assessing performance, safety, and fuel efficiency before producing physical prototypes.

4. Real-Time Monitoring and Control

Digital twins provide real-time insights into the status and performance of physical assets. This continuous monitoring allows for immediate response to anomalies or deviations from expected behaviour, enhancing control over complex systems.

Example: In smart cities, digital twins of infrastructure like bridges and traffic systems allow for real-time monitoring and management, improving safety and traffic flow.

5. Optimized Resource Management

Effective resource management is crucial for minimizing costs and maximizing productivity. Digital twins help in tracking and optimizing the use of resources such as energy, materials, and personnel. By analyzing real-time data, businesses can make informed decisions to reduce waste and optimize resource allocation.

Example: In the energy sector, digital twins of power plants enable operators to monitor energy consumption and efficiency, leading to optimized resource management and cost savings.

6. Enhanced Customer Experience

Digital twins can improve customer experiences by providing personalized services and products. By analyzing customer data and feedback, companies can create digital twins that reflect individual preferences and behaviours, leading to tailored offerings and enhanced satisfaction.

Example: In retail, digital twins of customer behaviour can help personalize marketing strategies and product recommendations, leading to improved customer engagement and sales.

7. Better Decision-Making

Decision-making is significantly enhanced through the insights provided by digital twins. The ability to simulate various scenarios and outcomes enables organizations to make more informed decisions, reducing risks and improving strategic planning.

Example: In urban planning, digital twins of cities can simulate the impact of new developments or infrastructure changes, aiding in better decision-making for sustainable growth.

8. Facilitating Remote Operations

Digital twins enable remote monitoring and management of assets, which is particularly valuable in industries where physical access is challenging or costly. Remote operations can be conducted with real-time data and insights, ensuring efficient management of assets from anywhere in the world.

Example: In oil and gas, digital twins of offshore rigs allow for remote monitoring and management, reducing the need for on-site personnel and improving safety.

Applications of Digital Twins Across Industries

1. Manufacturing

In manufacturing, digital twins are used to optimize production processes, improve quality control, and predict equipment failures. They allow manufacturers to create virtual models of production lines, test different configurations, and identify the most efficient setup.

Case Study: Siemens uses digital twins to model and optimize its manufacturing processes, resulting in improved production efficiency and reduced time-to-market for new products.

2. Healthcare

In healthcare, digital twins are applied to patient care, medical device management, and facility operations. They can create personalized treatment plans by simulating the effects of different therapies on virtual models of patients.

Case Study: Philips uses digital twins in its health technology solutions to monitor and manage medical devices, improving patient outcomes and operational efficiency.

3. Automotive

The automotive industry uses digital twins to design, test, and optimize vehicles. They simulate driving conditions, analyze vehicle performance, and test new features before physical prototypes are built.

Case Study: General Motors employs digital twins to accelerate the design and testing of new vehicles, leading to faster development cycles and improved vehicle performance.

4. Aerospace

In aerospace, digital twins are used for aircraft maintenance, performance optimization, and design. They monitor the condition of aircraft components, predict maintenance needs, and enhance overall safety and efficiency.

Case Study: Rolls-Royce uses digital twins to monitor and manage the performance of aircraft engines, reducing maintenance costs and improving operational reliability.

5. Energy and Utilities

Digital twins in the energy sector optimize the operation of power plants, grid management, and resource allocation. They provide real-time insights into energy production and consumption, leading to more efficient and sustainable energy management.

Case Study: GE Digital uses digital twins to optimize the operation of gas turbines and other power generation equipment, resulting in increased efficiency and reduced operational costs.

6. Smart Cities

In smart cities, digital twins model urban infrastructure, traffic systems, and environmental conditions. They help city planners and managers make data-driven decisions to improve urban living conditions and sustainability.

Case Study: Singapore uses a digital twin of the entire city to manage traffic, monitor air quality, and plan urban development, enhancing the quality of life for its residents.

Future Potential of Digital Twins

The future of digital twins holds exciting possibilities as technology continues to evolve. Advances in artificial intelligence (AI), machine learning, and the Internet of Things (IoT) will further enhance the capabilities and applications of digital twins.

1. Integration with AI and Machine Learning

Integrating digital twins with AI and machine learning will enable more advanced simulations, predictive analytics, and autonomous decision-making. AI algorithms will enhance the accuracy of digital twins, providing deeper insights and more precise predictions.

2. Expansion to New Industries

As digital twins become more sophisticated, their applications will expand to new industries and use cases. From agriculture to retail, digital twins will play a crucial role in optimizing processes, improving efficiency, and driving innovation.

3. Enhanced Interoperability

Future advancements will focus on improving the interoperability of digital twins across different platforms and systems. Seamless integration between digital twins and other technologies will enable more comprehensive and cohesive solutions.

4. Increased Adoption of IoT

The growing adoption of IoT devices will provide even more data for digital twins, enhancing their accuracy and functionality. Real-time data from a vast network of sensors will enable more detailed and dynamic virtual models.

5. Advancements in Visualization and Interaction

Future developments will enhance the visualization and interaction capabilities of digital twins. Improved virtual and augmented reality interfaces will allow users to interact with digital twins in more immersive and intuitive ways.

Digital twins are revolutionizing modern industry by offering a wealth of benefits, including enhanced predictive maintenance, improved operational efficiency, and better decision-making. Their applications span a wide range of sectors, from manufacturing to healthcare, and they hold immense potential for the future. As technology continues to advance, digital twins will play an increasingly vital role in driving innovation, optimizing processes, and shaping the future of industry. Embracing this technology will enable organizations to stay ahead in a rapidly evolving landscape and unlock new opportunities for growth and success.

Understanding the Basics of Cybersecurity: Tips for Protecting Yourself Online